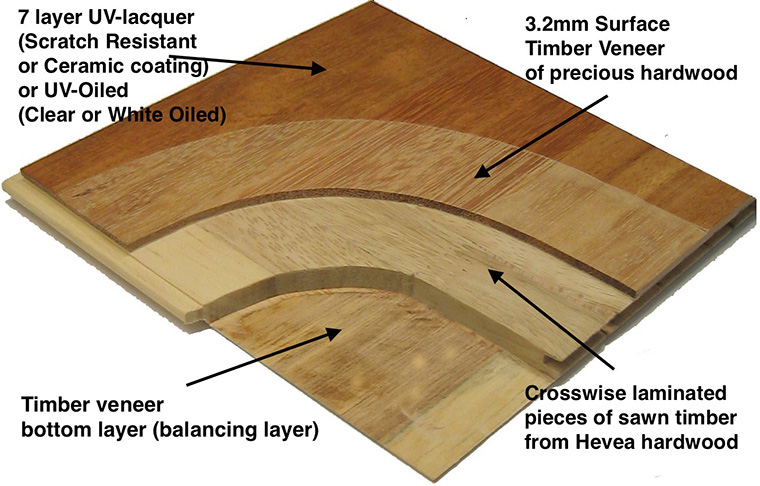

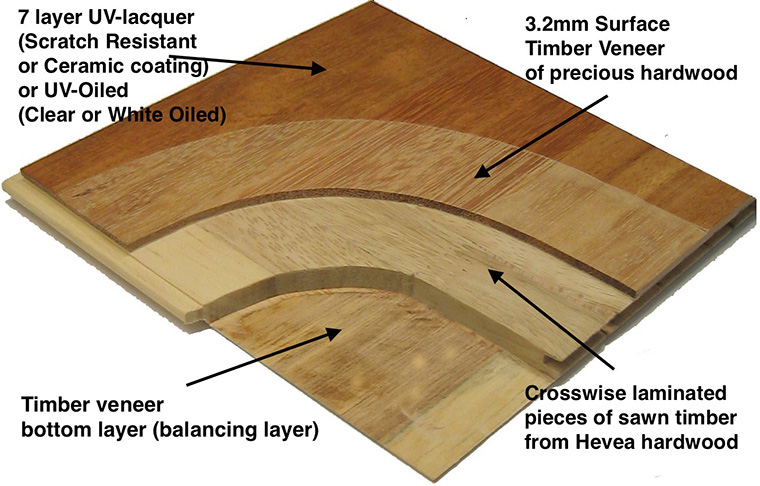

Woodline Parquetry – Technical specifications

Available in a viriety of surface treatments an finishes some which include UV lacquered, UV oiled, Smoked, Fumed, Antiqued or unfinished

3.2mm precious hardwood species e.g Brazilian Cherry, Euro Oak Etc

Crosswise laminated pieces of sawn Hevea hardwood

Timber Veneer bottom layer (balancing layer)

1220 to 3000mm Species depending

145 to 400mm depending on species

Valinge click (Glueless installation)

25 Years Heavy Domestic

5 years Moderate Commercial use.

Density

Bending strength Nmm2

Shrinkage from green to 0

Pine (Nordic)

490

100

12.1

Spruce (Nordic)

490

78

11.9

Poplar (Balsamic)

390

48

10.8

Hevea Brasilienis (Rubberwood) is a plantation species that yields natural latex in it’s harvest-able lifespan. When the trees have reached and age where latex yield is no longer adequate, the trees are harvested for lumber. This process of felling and replanting occurs every 25-30 years.

Rubberwood is widely accepted as an excellent substitute for for many hardwood species due to its excellent physical and mechanical properties.

It is a known fact that rubber-wood core in 3 layer engineered floors is stronger than other species used. Being a hardwood species with similar density characteristics or Oak, Rubberwood enhances greater dimensional stability and withstands external pressure e.g temperature, moisture and air.

We take pride in the fact that majority of our 3 layer engineered wood flooring composition make use of renewable timber resources. 75% of each plank is made up of plantation species and 25% is from precious timber veneers, that we take great car in sourcing from FSC certified forests. Making this product environmentally friendly.

The diagram below displays the Flooring composition of the various types of floors that are available.

Maintenance of UV lacquered floors

The Woodline Parquetry UV lacquer coating is scratch resistant and easy to maintain.

Doormats inside and outside entrances prevent dirt and grit that cause unnecessary wear to the floor.

Protective pads on furniture and chairs will assist in avoiding marks and scratches on the surface of the floor.

Normal cleaning

Use a broom to sweep or vacuum cleaner to prevent dirt, dust or grit from scratching or dulling the surface.

When necessary, the floor can be cleaned with a damp (well-wrung) cloth. Add a few drops of a mild detergent to water. Never splash water on a wooden floor!

Spills or spots must be wiped up immediately with a damp cloth.

Spots must be removed as soon as possible with a mild detergent.

Repairing

A scratch or crack in the floor can be repaired with putty. A deep scratch can be puttied several times if left to dry between applications.

All Woodline Parquetry flooring can be sanded several times. This should only be done by a professional.

Maintenance of UV Oiled Wood floors

Oil treated floors offer you a very special finish and create a beautiful and natural living environment. In order to maintain the beauty of your oil finished floor, it is especially necessary to care correctly for the floor right after installation. With the right care, the oiled floor will become increasingly easy to clean and more hard wearing.

Doormats inside and outside entrances prevent dirt and grit that cause unnecessary wear to the floor.

Protective pads on furniture and chairs will assist in avoiding marks and scratches on the surface of the floor.

After installation care

Woodline Parquetry UV-oiled flooring is pre-finished with UV-oil from the factory and is ready for use in

both domestic and commercial areas. We recommend to clean the floor immediately after installation, with soap.

Normal cleaning

For daily cleaning, sweep or vacuum. For dustier floors, clean with a well wrung damp cloth regularly. When cleaning oiled floors, soap is added to the water (1/8 ltr soap into 5 ltr lukewarm water).

The soap has two functions: it cleans the floor and at the same time forms a protective soap film on the floor making the surface more resistant.

Tips

Always work with two buckets of water – one with soap water and one with clean water for rinsing the mop or cloth.

If you use a special cleaning or care product (water based wax agent) for oiled floors, please test the product on a small, less visible area of the room. Some products may not be compatible with the oil finish.

Whenever applying cleaning and care products to your floor, always ensure no standing water is left behind. This can damage your flooring (swelling).

Maintenance Oil

After a certain period of use, the oiled floor may look slightly worn and matt. Maintenance oil may be used. This should be done by a professional.